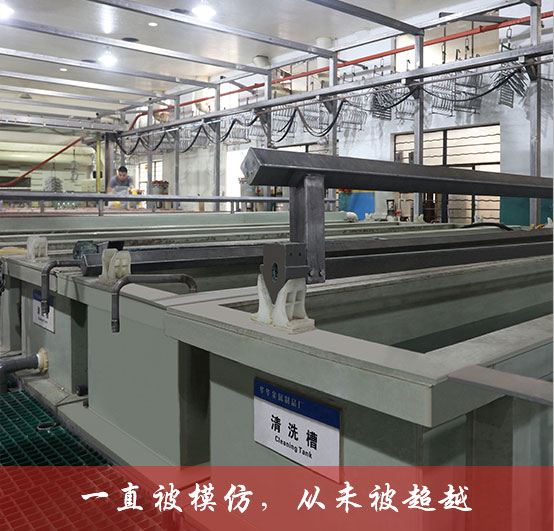

Yuhuan Huahua Metal Products Factory was established in 2003, specializing in aluminum anodizing process. We have been working on aluminum anodizing for more than ten years, high-end and rich production experience in professional processing such as anodizing on aluminum surfaces.

The company has passed TS16949 quality management system certification, mainly producing and processing aluminum surface anodizing, hard anodizing, electric conductive oxidation, oxidation coloring, etc. Anodizing aluminum parts surface such as military parts, aviation parts, motor parts, optical parts, auto parts, motorcycle parts and electrical parts.

After hard anodizing processing, the surface can get a thick oxide film with high hardness, the oxide film can reach 25 to 100 microns, if there is a special need, it can reach 200 microns, the hardness of the aluminum film varies according to the material composition, the max hardness can reach about HV650. The pure aluminum film has the highest hardness and does not corrode in the salt spray test for several thousand hours.

To clean the marks on titanium alloy, the following steps can be taken:

The appearance of crystal spots on aluminum materials is due to the segregation and segregation of alloy

Aluminum is an active metal, and the wear resistance and corrosion resistance

Anodizing is a highly favored processing technology in the aluminum alloy industry.

1. The thickness of the film is uneven. The possible reason is that the temperature and concentration of

1, wash water is not clean, should strengthen the water wash.2, the water used for washing